Thermal Compensation Strategy for CNC Lathes

Introduction

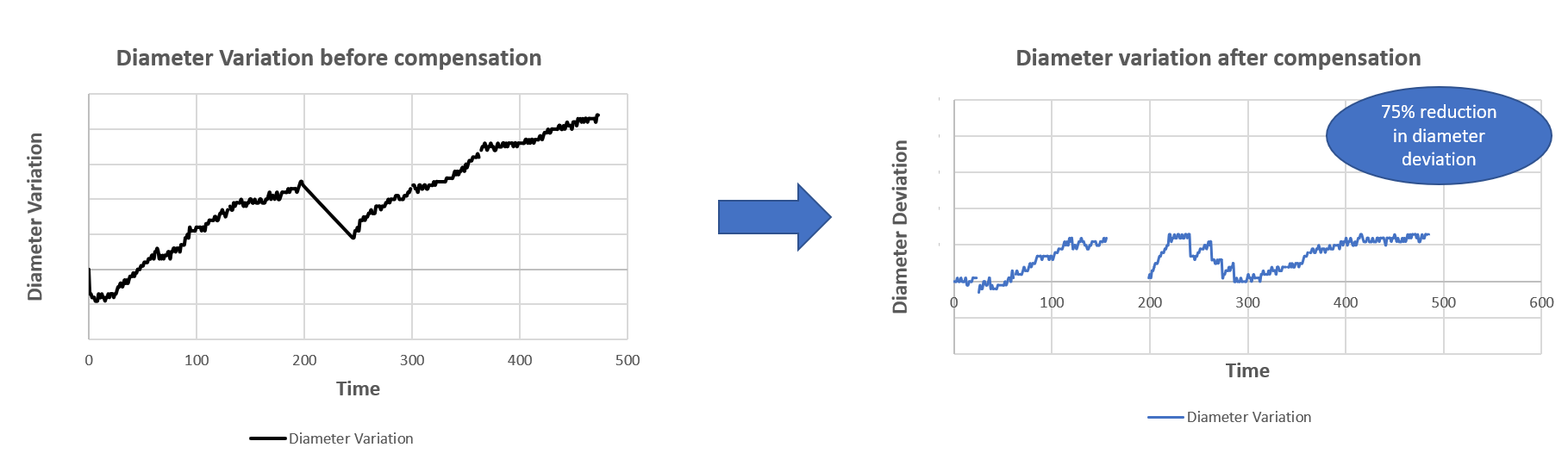

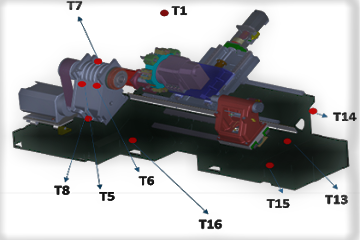

The thermal behaviour of the machine has a large impact on the structural deformation of the machine, which in turn affects the accuracy of the machined parts. By predicting the behaviour of the structure with respect to the thermal variations, it is possible to provide corrections at the tool point so that the accuracy achieved on the component can be improved. The present day control systems used on the Lathe is capable of automating the corrections with the data generated from specific algorithm unique to the product.

Overview

Research to Technology

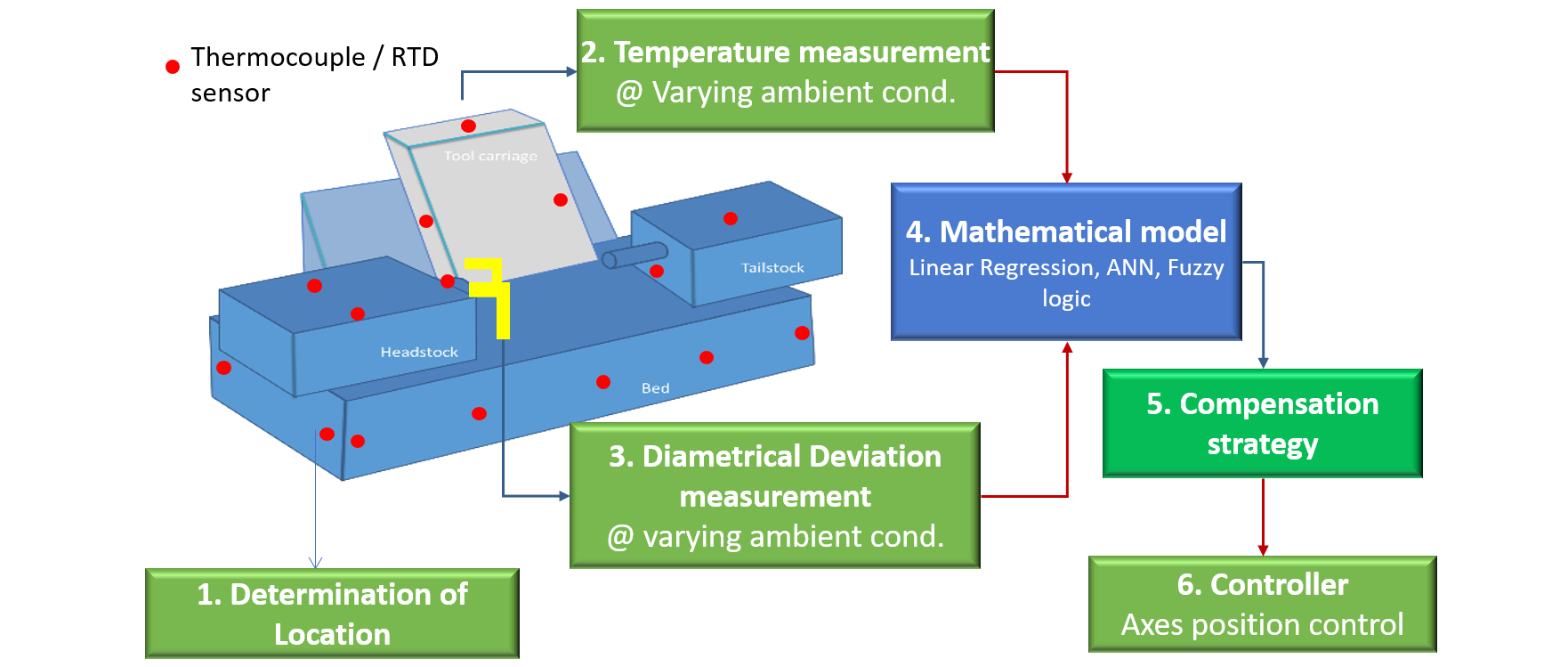

Methodology

Key developments

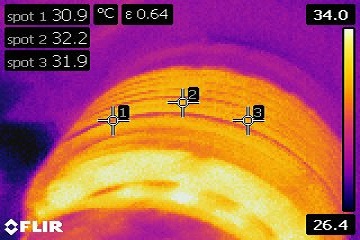

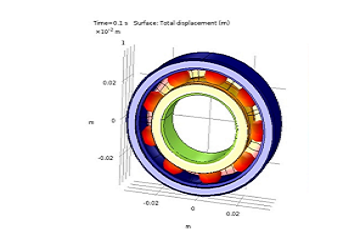

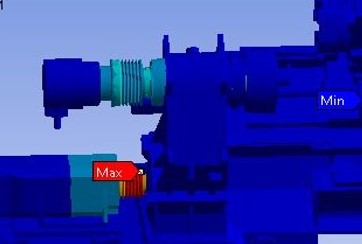

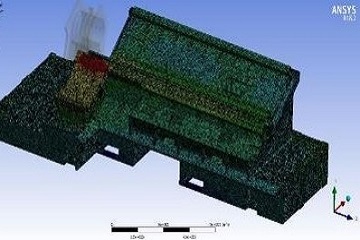

Multiphysics analysis (MBD+HT)

Project Members

Gallery

Funded by